According to Stephen Brennock, an oil analyst at PVM Oil Associates Ltd., one area of...

OFTEC Ireland, the body representing the liquid fuel heating industry in Ireland, is urging the...

Maine Energy Marketers Association have announced that all oil dealers in Maine and New England...

Minister for the Environment, Richard Bruton, has said he “cannot contemplate” a scenario where the oil...

Oil & Gas Technology Centre (OGTC) based in Aberdeen is pushing an initiative called the...

Certas Energy has announced plans to develop an HGV refuelling bunker facility at the ‘fechan...

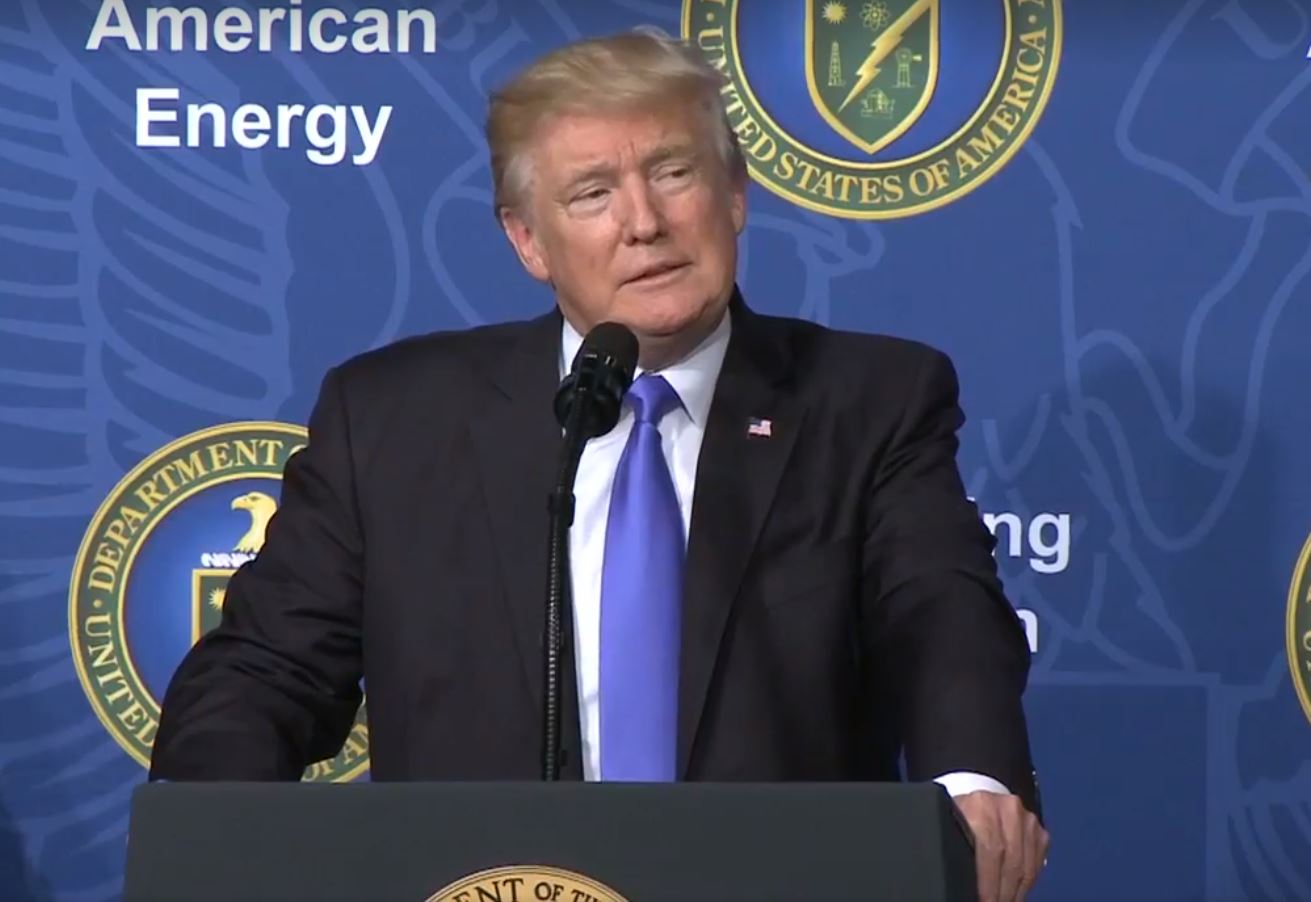

Trump on Monday said he believed China was sincere about wanting to reach a deal,...

The Seattle City Council voted unanimously on the 23rd of September to phase out the...

Shares in Providence Resources fell more than 5pc yesterday after the group once again extended...

“China should not have put new Tariffs on 75 BILLION DOLLARS of United States product...